This article details the catastrophic failure of a Marineland aquarium, revealing a surprising cause and highlighting critical lessons about aquarium construction and safety. The author recounts the shattering of the tank's bottom panel, initially attributed to a central point of failure, but ultimately traced to a hidden void created beneath the substrate by a fish's excavating activities over six months. This unexpected discovery underscores the importance of considering even seemingly minor factors in aquarium maintenance and setup.The investigation further exposed a significant design flaw: a disparity in glass thickness between the bottom (1/4 inch tempered) and side (3/8 inch annealed) panels. This cost-cutting measure by Marineland compromised the tank's structural integrity, leading to the devastating collapse. The incident serves as a cautionary tale, emphasizing the need for thorough research when selecting an aquarium, prioritizing robust construction and uniformly thick, high-quality glass, especially for the bottom panel, regardless of initial cost. The author's experience underscores the importance of safety and long-term reliability over short-term savings.

Read more: 5 Amazing Lava Rock Aquarium Caves

The Catastrophe and Initial Investigation

A heartbreaking event unfolded in my aquarium: the bottom glass panel catastrophically shattered. The initial assessment suggested a central point of failure, mirroring the video's apparent depiction of air bubbles rising. However, a closer examination revealed a different story.

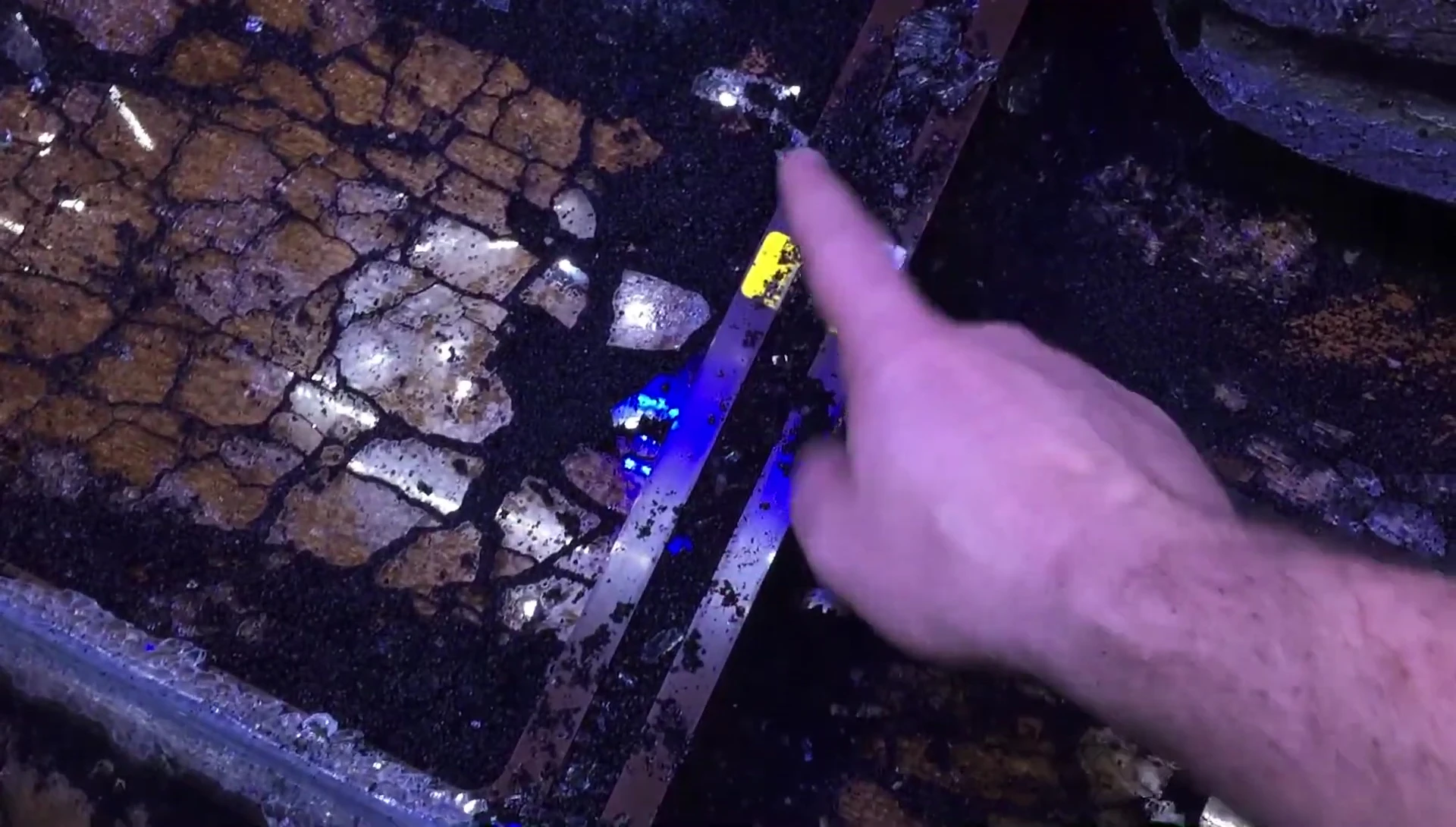

The crack pattern, clearly visible, indicated a failure point significantly lower in the tank. This was surprising, considering the weight distribution wasn't concentrated there. This location pointed to a potential underlying cause.

Uncovering the Root Cause: A Fishy Culprit?

The real culprit behind the tank failure was quite unexpected: a fish. Specifically, a fish known for its excavating habits had been diligently working beneath the rocks for six months. This created a hidden void under a significant portion of the tank’s weight.

Its actions, coupled with a possible rock slide or subtle weight shift, led to the ultimate collapse. The crack pattern radiates outward from the spot where the most significant rock load was likely concentrated.

Tank Specifications and Quality Concerns

The tank itself was a Marineland model, marked as “tempered” and dated 2001. While the label indicated tempered glass, a closer inspection revealed a critical difference in glass thickness between the bottom and side panels.

The bottom glass was 1/4 inch thick tempered glass, while the sides were thicker at 3/8 inch annealed glass. This disparity indicated a cost-cutting measure which ultimately compromised the tank's structural integrity.

The Aftermath and Lessons Learned

The aftermath involved the arduous task of removing debris and relocating the fish. Thankfully, all the fish survived the incident and were safely transferred to a temporary tank.

This experience highlights the importance of understanding aquarium glass thickness and construction. Using a thicker, more robust glass, especially on the bottom panel, is crucial to prevent similar incidents. I'm upgrading to a new tank with half-inch tempered glass.

Conclusion and Recommendations

The Marineland tank failure underscores the importance of thorough research and high-quality materials when choosing an aquarium. While the tank's label indicated it was tempered glass, the thinner bottom panel proved to be a critical weakness.

I strongly advise investing in aquariums with thicker, uniformly thick glass, particularly on the bottom. My future tanks will prioritize higher-quality construction, even if it means a higher initial cost. This unfortunate incident was a costly lesson learned, emphasizing quality over cost-cutting.